Supply Chains will change approaching 2030 but to what?

Summarising likely changes

In the near future, many country’s economies will be different and not just a version of that experienced for the past thirty years. The reasons are not all economic but are likely to drive uncertainty as disruptions and changes become more frequent, with unknown outcomes.

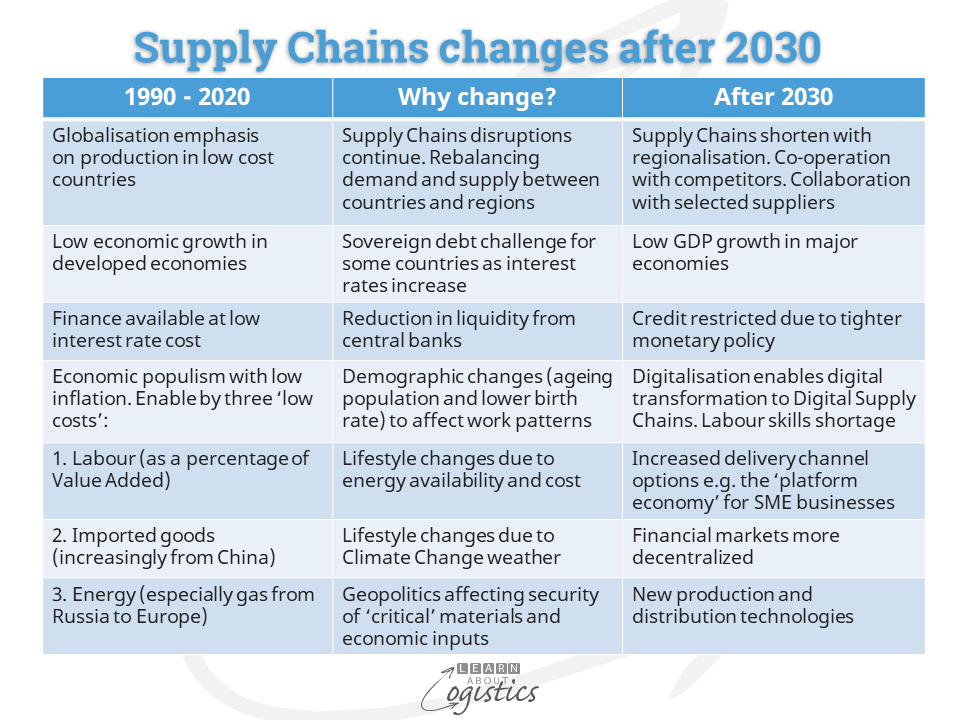

The Learn About Logistics blogposts through November have discussed aspects of changes that could affect your organisation’s supply chains. These are summarised in the table below.

A recent report

A Reuters Events report, (available for subscribers) titled A generational shift in sourcing strategy. Although written from a mainly European perspective, the questions raised are relevant to businesses in all regions.

The main findings in the report are that supply chains will rebalance and deleverage from concentrated areas of production. They will move towards locations that are closer to end markets and to a wider range of low-cost countries. This is to provide the flexibility and resilience required for reduced delays, transport costs and shortages of materials and intermediate products that are traded over long distances.

Companies will need to look more closely at the total landed costs or total cost of ownership (TCO) and the impact cost of not meeting market demand. While it remains unclear how pervasive the move to on-shoring and near-shoring will be, increased geopolitical uncertainty and changing trade policies are an important determinant that are already impacting supply chain decisions in some business sectors.

Terminology

- Reshoring: The practice of moving organisational productive capacity to the same market as where the final product(s) is utilised or sold.

- Nearshoring: The practice of moving organisational productive capacity near to where the final product(s) is utilised or sold.

- Near-sourcing: The practice of sourcing items or productive capacity from a supplier near to where the final product(s) is utilised or sold.

The top five reasons for changing sourcing location are noted as:

- Shorten supply chains to increase flexibility

- Limit reliance on single sources for materials

- Limit risk across supply chains operations

- Shorten supply chains to reduce transit time

- Increase control over supply chains operations

The emphasis is not to identify where production costs are lowest but instead prioritise shorter supply chains, flexibility and risk mitigation to improve reliability, proximity, speed, visibility and sustainability ahead of cost. This is to provide reliability of delivery, proximity to end markets and labour skills mix that assist productivity.

The report provides a comment concerning risk in supply chains: “So, the leading question today is how to measure and objectivise the risks associated with geopolitics. That’s the key underlying question; all the rest is relatively easy. You have quantitative metrics: You have inflation; you have unemployment; you have education levels; you have taxation rates; you have governance structures. All of that you can quantify to a certain degree. What you cannot quantify that easily is the geopolitical risk. This is where I’m focusing.” Karel Stransky, Head of Corporate Industrial Advisory, Occupier Services EMEA, Colliers

Identifying and securing alternative suppliers will be gradual

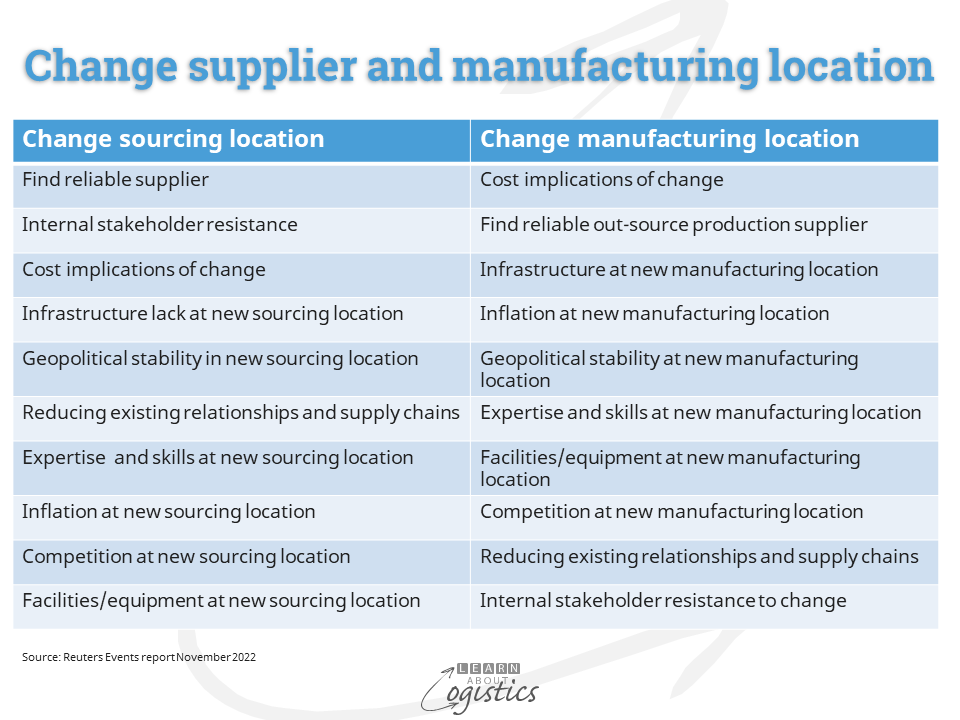

The table below lists the main barriers to changing suppliers and production locations. It indicates levels of importance for the designated factors and therefore the risks that must be identified and mitigated.

Positioning of factors in the list indicates why moving manufacturing locations is more challenging than a change to sources of supply. Manufacturing is riskier, more expensive and time consuming and therefore fewer businesses will consider this change.

However, the decision is industry dependent, with Consumer-Packaged Goods (CPG) and Fast-Moving Consumer Goods (FMCG) able to bring new capacity online relatively quickly, verses (for example) pharmaceutical and electronics, which require a higher degree of technical expertise and more costly equipment.

0 Comments